BELLS ENGINEERING PRODUCTS

info@bellsengineering.co.uk

01753 567788

Information

The details below act as a reference guide to assist with the selection of valves in industrial applications.

This is not intended to be a complete guide and our engineers can assist you will specific requirements of your application.

Gate Valve

- Gate valves should be left in the fully open or closed position for long periods of time to assure satisfactory operation.

- Fine control or throttling can induce serious gate erosion.

- Suitable for use with water, gas and chemical duties.

- Overhead clearance for high stern, high lift valves is needed for installation and maintenance.

- Not suitable for service with heavy solids in suspension.

Globe Valve

- Ideal as steam valves used as stop and control valves.

- They are not generally suitable for handling virulent sluggish, slurry type liquids not noxious/toxic gases due to the flow and difficulty of providing an effectively packed gland.

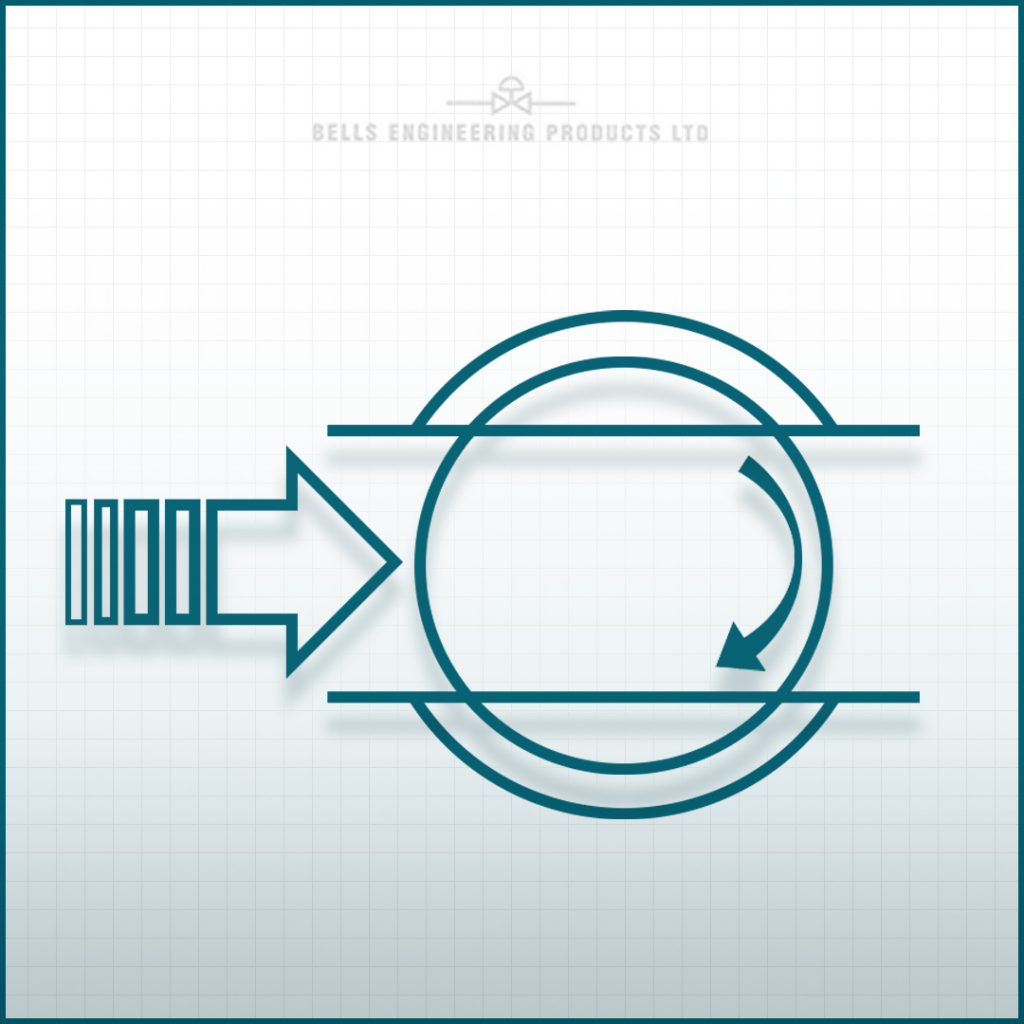

Ball Valve

- For high pressure / high temperature services.

- Wide choices of material and size range.

- Generally low torque, low pressure drop and simple valve action.

- Not suitable for abrasive duties, high sterility requirements, coagulating fluids and throttling applications.

Plug Valve

- The rapid acting valves are available with either taper or parallel plugs.

- They offer a very full capacity and streamlined flow in the open position.

- For effective operation lubricant under pressure is injected between the plug face and body seat.

- PTFE lined sleeves can be fitted to negate the requirement for lubrication.

- Pressure loss is minimal and high pressure easily handled with both liquids and gases.

- Different valve types are available where product purity, solids handling or a choice of materials/linings are required.

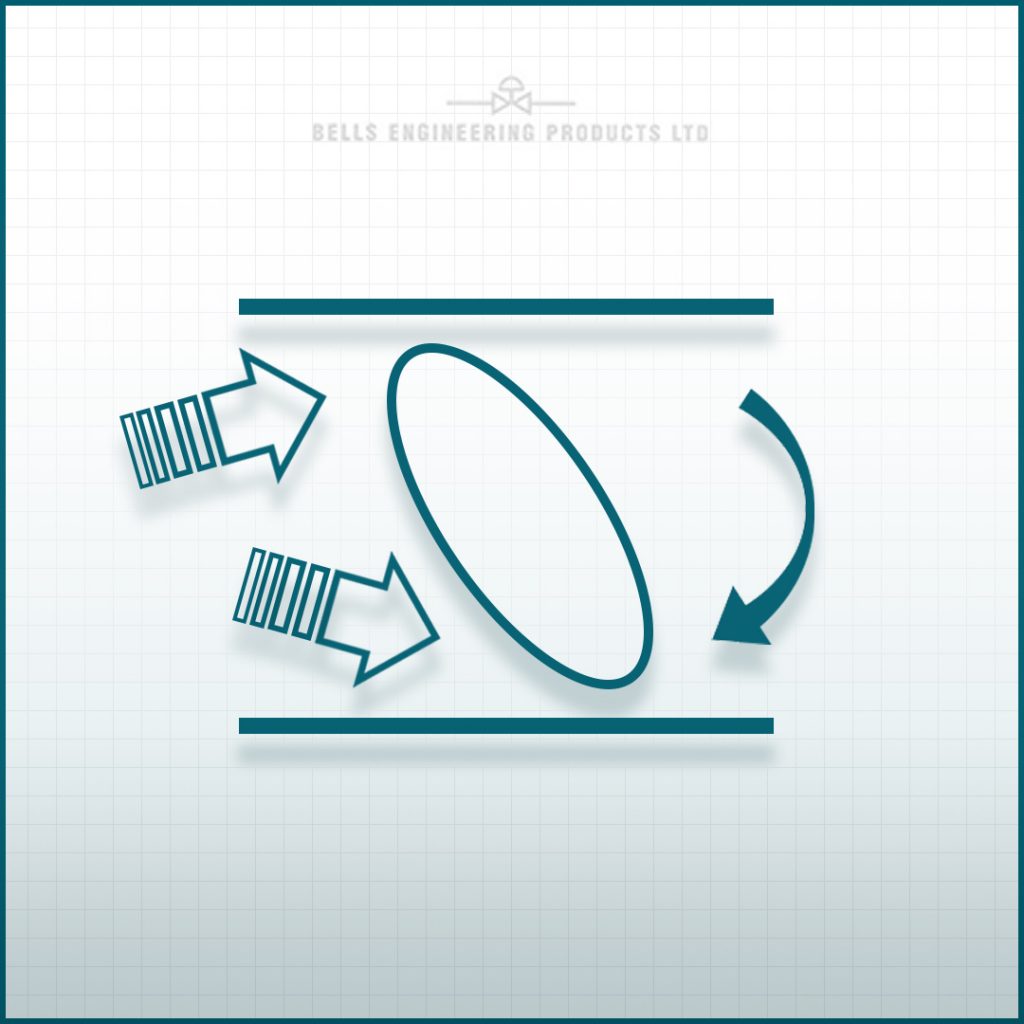

Butterfly Valve

- A wide choice of basic body/disc materials is readily available with linings ranging from natural rubber to PTFE.

- Excellent for systems requiring a lightweight compact unit which is equally good, in general terms, for on-off and regulation work.

- Large/heavy solids services should be avoided; as should too-rapid disc operation.

Diaphragm Valve

- Suitable for on-off, throttling, pressure and high vacuum, air or hazardous chemicals. Maintenance is practically nil.

- Not a high temperature valve.

- ‘Straight-through’ versions are available.

- Unsuitable for high pressure lines wherever instantaneous closure or opening when required.

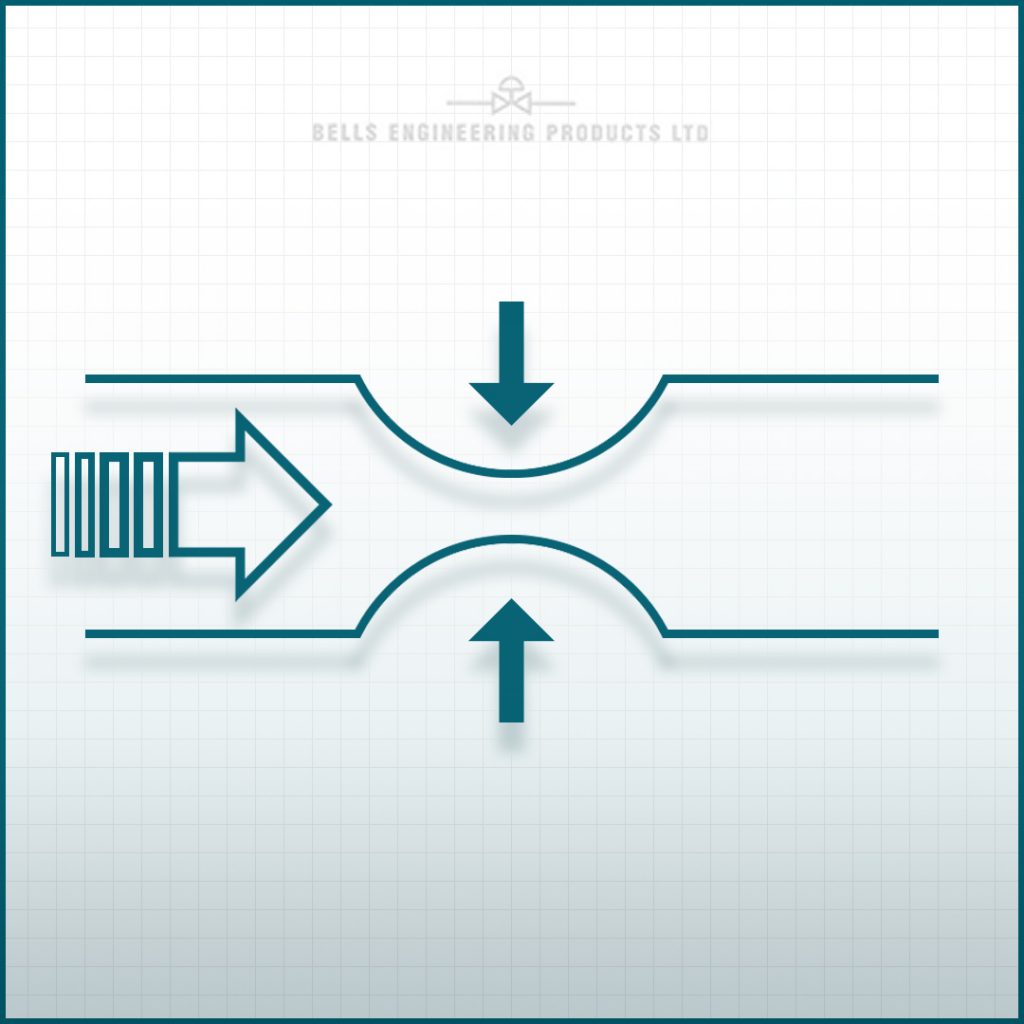

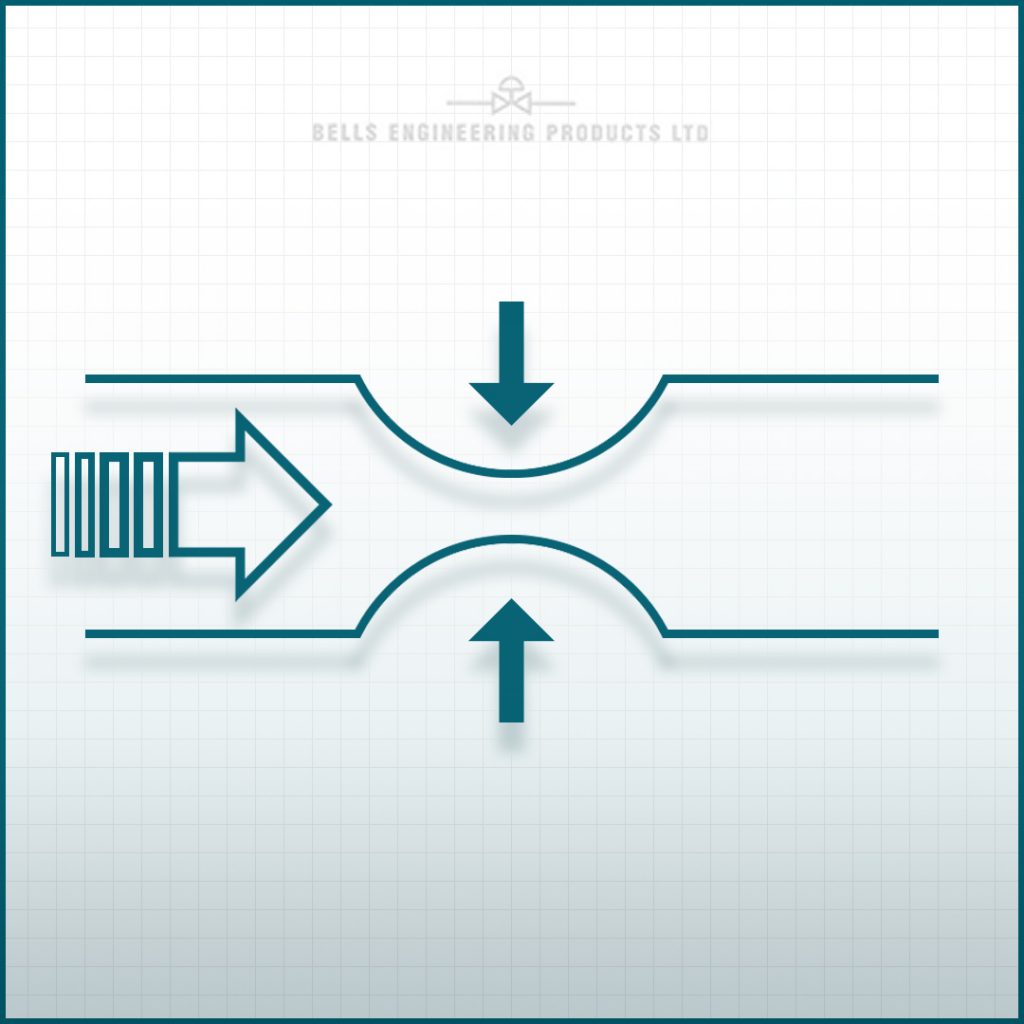

Pinch Valve

- Pinch valves are probably the simplest and most efficient valves available.

- They comprise a rubber hose or sleeve which is clamped in a pipeline and pinched or squeezed together to stop or control the flow.

- Fully open, the valve is similar to rubber lined pipe.

- In the fully open or fully closed positions there is little or no wear.

- A closed pinch valve should seal bubble tight.

- They are mainly used where abrasion, sewerage, solids handling and/or corrosion is a factor. They are the ideal slurry valve and have many advantages over other types of valves in these conditions.