BELLS ENGINEERING PRODUCTS

info@bellsengineering.co.uk

01753 567788

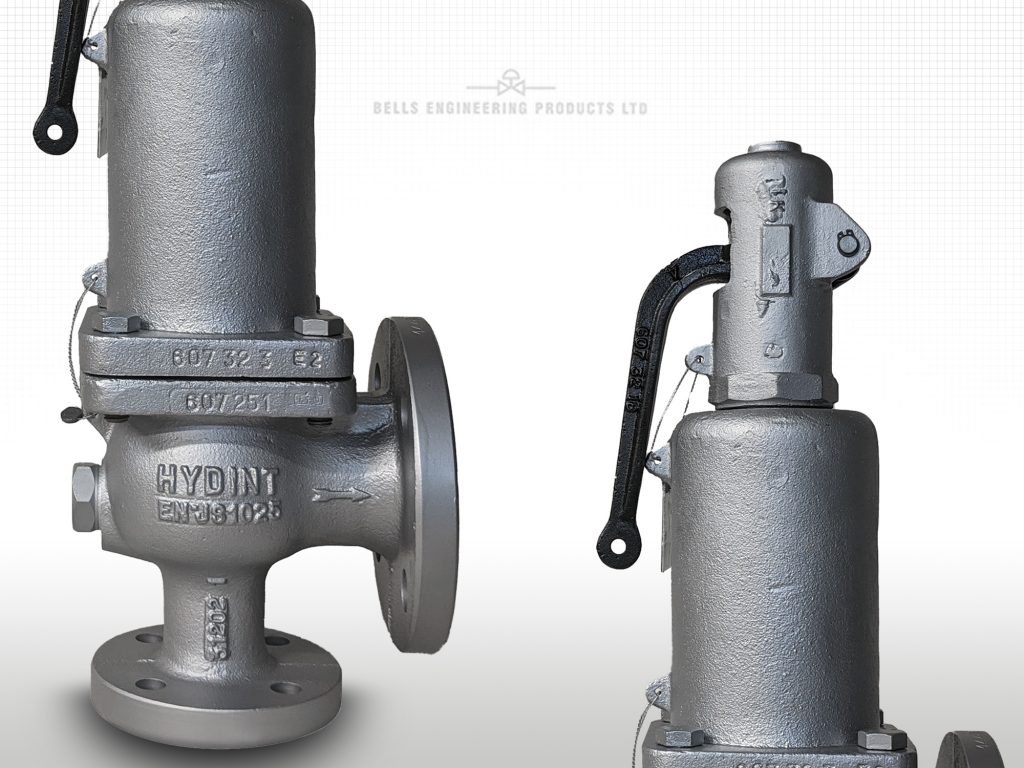

Below is an example of a fully overhauled safety valve

The tables below summarise our three-stage overhaul process.

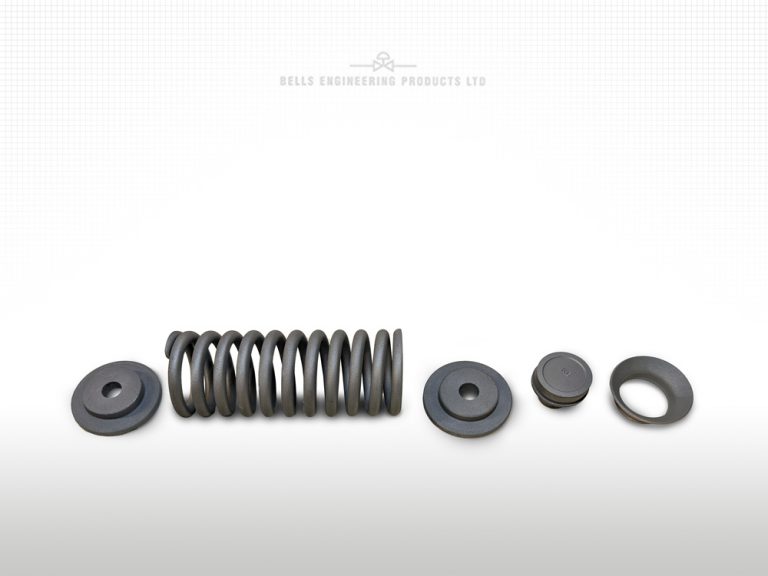

Stage 1: Valve Stripping

The valve is stripped into the following components:

- Body

- Bonnet

- Cap

- Spring

- Spring plates

Stage 2: Cleaning, shot blasting and visual inspection

The guide plate and lever is shot blasted and visually inspected for any flaws.

When satisfied, components are:

- Sprayed

- Spindle cleaned

- Visually inspected and polished

- The collets and adjuster are then cleaned and visually inspected

- The skirt is removed from the disc, cleaned and visually inspected

- Disc polished to remove any marks for tight seal

- When complete, skirt and disc reassembled

- Valve body seat is ground to remove any marks

Stage 3 Assembly & Testing:

Valve assembled and pressure tested with oxygen free nitrogen to ensure valves lift at set pressure and fully reseats.

We use a UKAS calibrated pressure gauge with accuracy of 0.05% full scale. This is sent away annually for calibration to ensure it is with specification.

When valve has passed test we attach aluminium tag with individual identification number, set pressure and test date.

We then issue your test certificate.